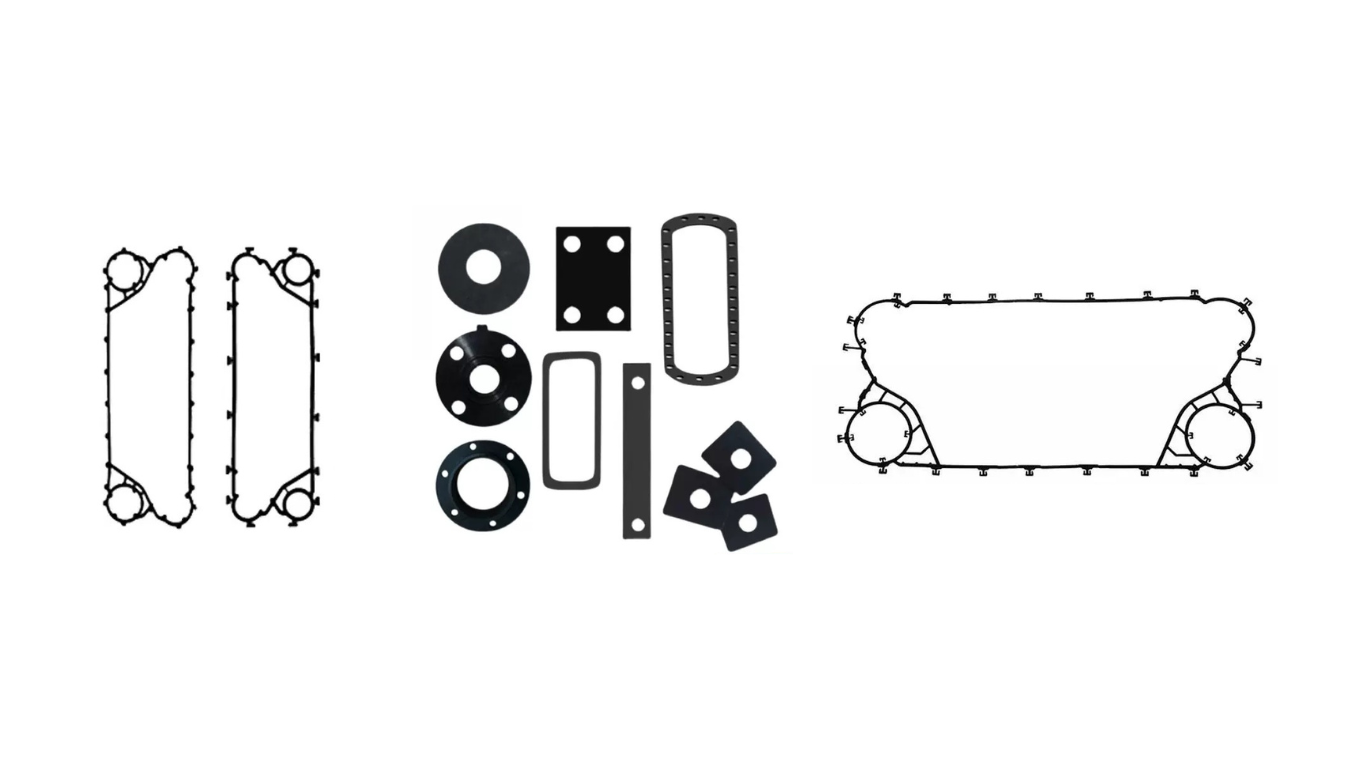

Rubber Gaskets

Purpose:

- ● Seal joints to prevent leaks under compression

- ● Absorb vibrations and reduce noise

- ● Provide cushioning between components

- ● Protect against dust, moisture, and contaminants

Materials:

- ● NBR – Excellent oil, fuel, and grease resistance

- ● EPDM – Outstanding weather, ozone, and steam resistance; great for outdoor use

- ● Silicone – High and low temperature resistance; suitable for food, medical, and clean-room applications

- ● FKM – Superior chemical and heat resistance for harsh environments

Applications:

- ● Automotive engines and exhaust systems

- ● HVAC systems and duct-work

- ● Industrial machinery and pumps

- ● Electrical enclosures and panels

- ● Plumbing fixtures and water systems

- ● Food processing and pharmaceutical equipment

Advantages:

-

- ● Flexible and easy to conform to surface irregularities

- ● Effective sealing under compression

- ● Durable across wide temperature and pressure ranges

- ● Available in custom shapes, thicknesses, and hardness levels

- ● Cost-effective for both standard and complex sealing needs

Types:

- ● Flat Gaskets – Simple, flat-profile for flanges and covers

- ● Custom Die-Cut Gaskets – Tailored shapes for specific applications

- ● Molded Gaskets – 3D sealing surfaces for more complex designs

- ● Sponge/Foam Rubber Gaskets – Ideal for low-pressure or weather sealing

Rubber gaskets are vital sealing components across countless industries. Their versatility, material options, and ability to handle mechanical stress and environmental exposure make them indispensable for leak-proof and long-lasting assemblies.